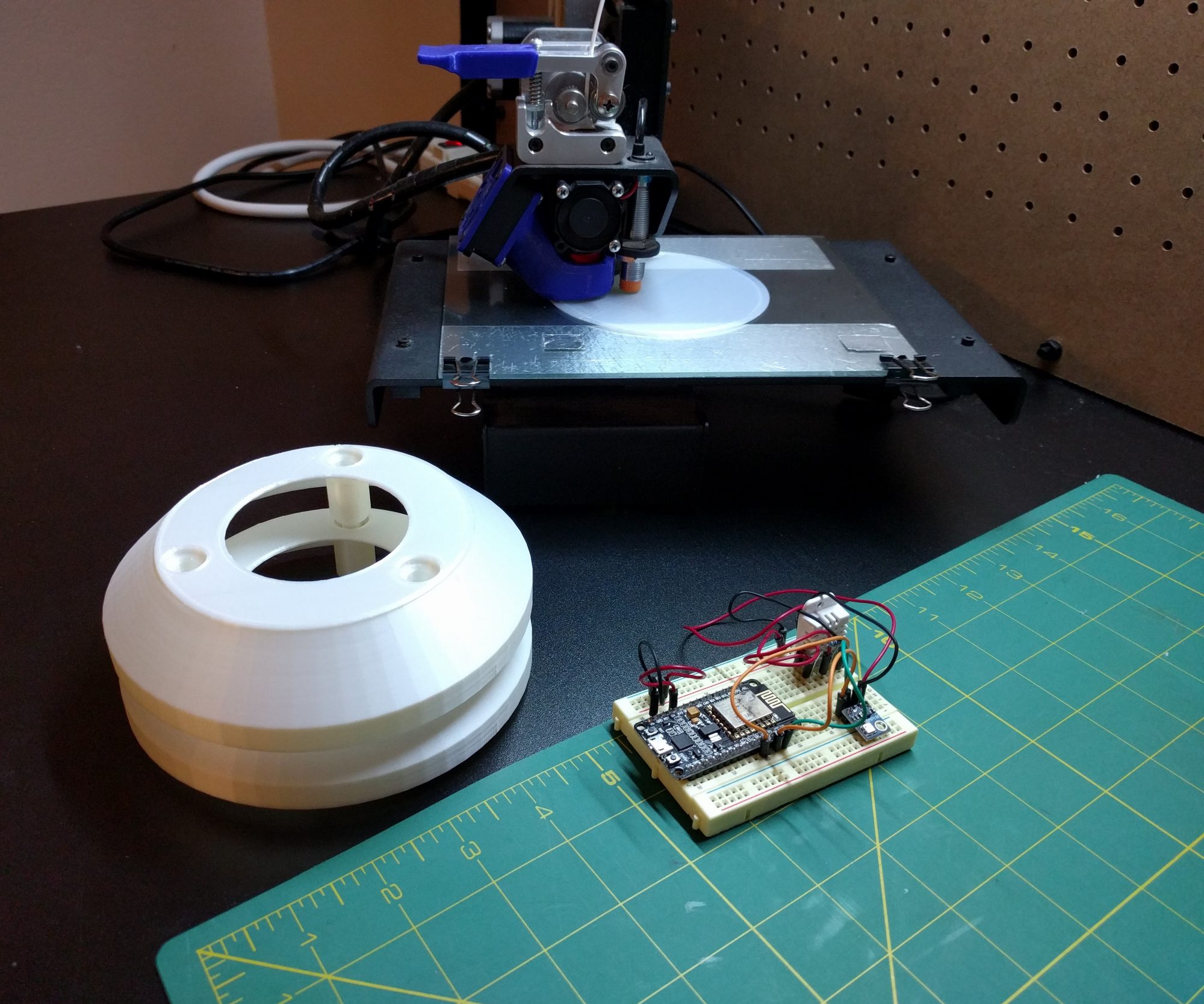

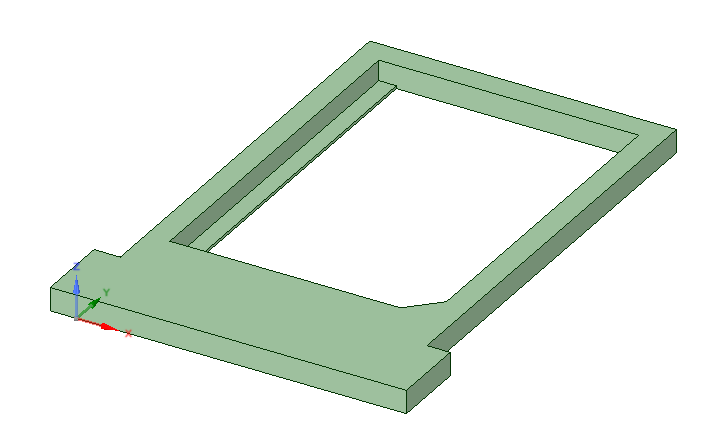

The weather station is complete!… again. I found a new home for my weather station. After my housing melted last summer my weather station had been sitting in a tote while I decided what to do, see this post here. In the mean time, I figured out how to reconnect the power to my shed. The battery I had used for the weather station wasn’t lasting long enough and putting the station to sleep between updates let the battery shut off and it wouldn’t come back on. This was the perfect opportunity to find a new home for the weather station and a new source of power. I reprinted the solar shade and designed a new mount to attach it to the side of the shed. I drilled a hole through the wall of the shed, installed the mount with a few screws and sealed with whole thing with some silicone caulking.

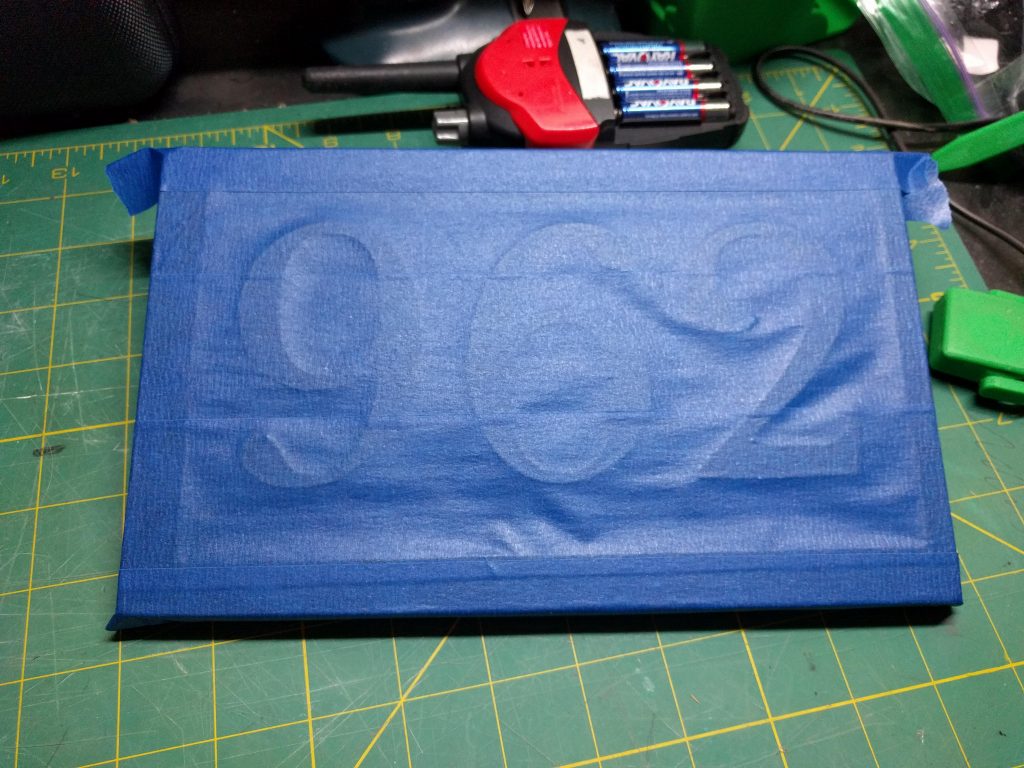

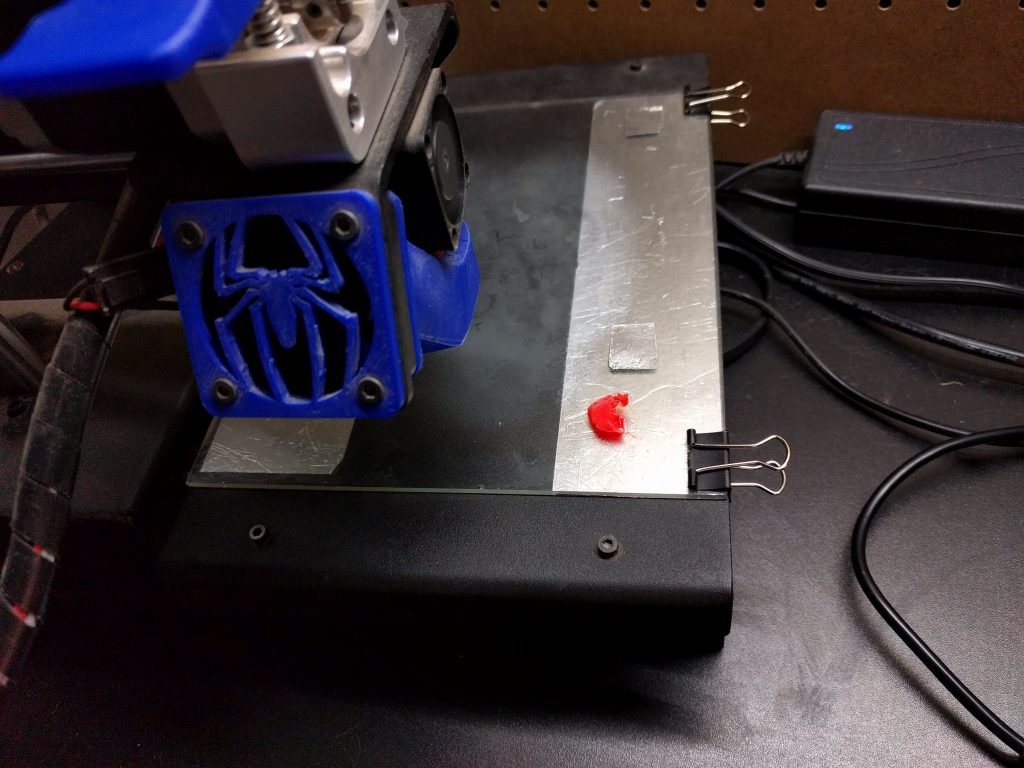

I ran out of filament during the print of the base and struggled to recover the print. My printer doesn’t have a pause button, so I tried splicing the new PLA filament by hand with just a lighter and my pliers. The splice broke as it was going into the extruder wheel, and it took almost a full layer before I was able to get the new PLA through the extruder. This filament wasn’t enough either and quickly realized that another splice wouldn’t work. This time, while it was printing infill, I swapped out the filament just like I would normally change colors before a print. That worked great and I barely had any issues with the transition. After the print finished, the part split at the first material transition. I used 5-minute epoxy to glue it back together. My infill spacing was slightly larger than a toothpick, so I inserted several to keep the part aligned. I wasn’t too considered about the finish of the seam and painted it white to match the top of the shade.

The screws I used to mount the base were a little long, so I added a piece of scrap wood to prevent anything from getting cut on the screw ends.

I made sure the cable hung down lower than the power strip so that if there was a leak, the water would drip off the bottom of the loop and not get into the power supply.

I taped the end of the USB cable to prevent any silicone getting on the connector and fished it from the inside of the shed out through the hole in the mount.

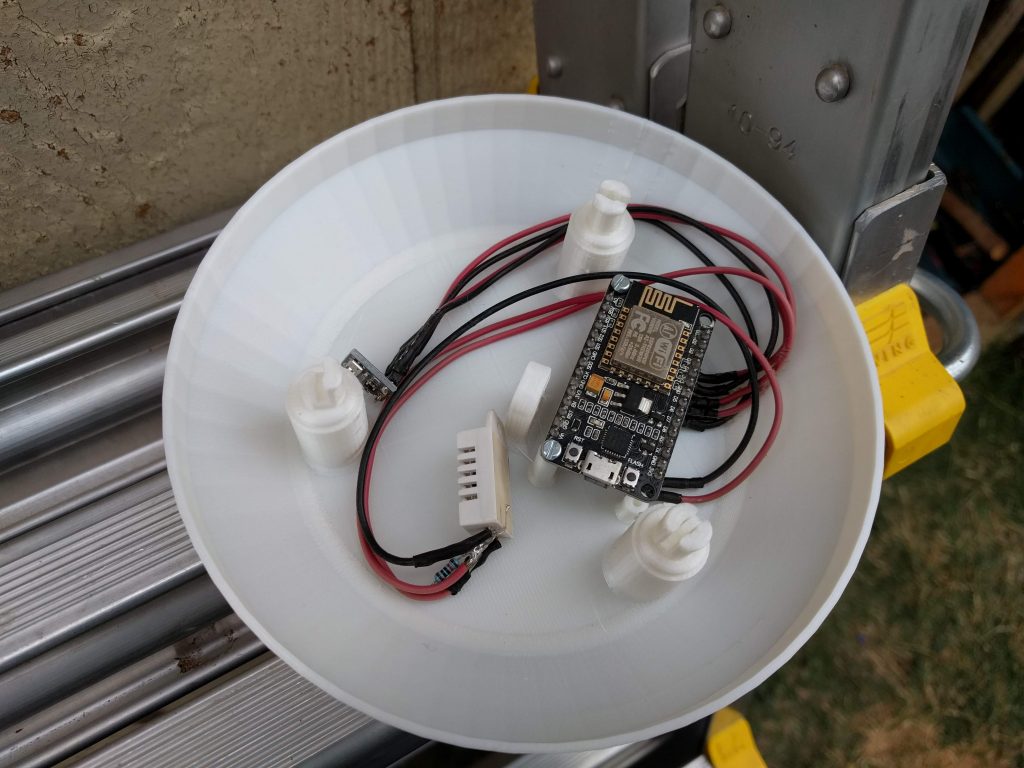

I connected the electronics to the top of the solar shade. (I think I broke two of the mounting holes the last time I did this.)

Put the lid on and everything is done.

After a few days, I realized that I wasn’t getting any value out of having the weather station up. I downloaded the Weather Underground app for my phone and set it up to pull data from my weather station. Now I know what temperature it is at home every time I unlock my phone. Looks like a nice winter night here in Arizona.